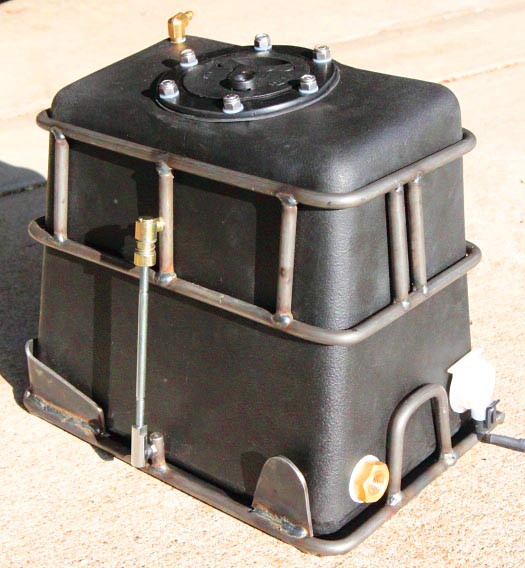

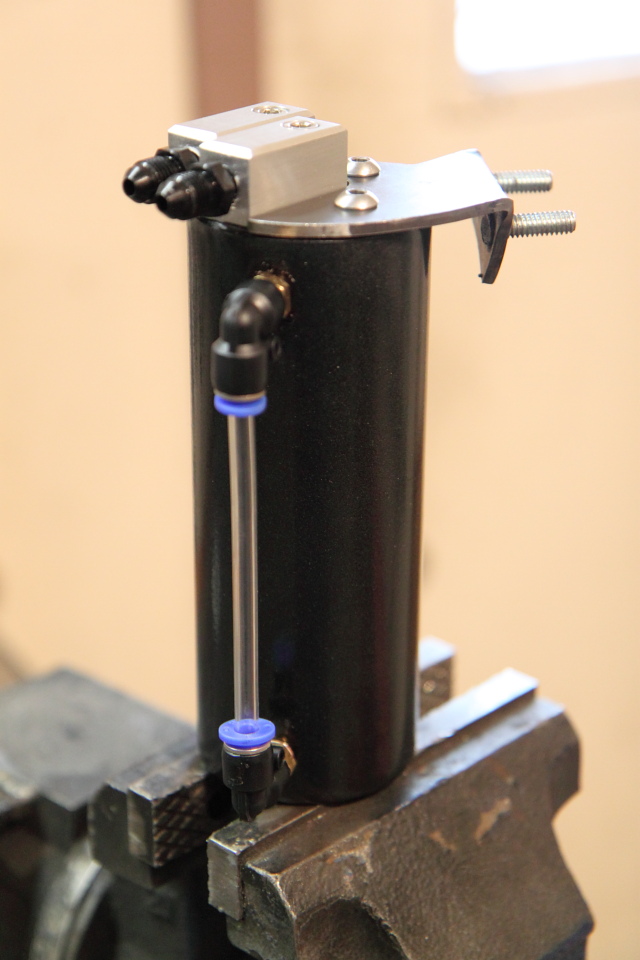

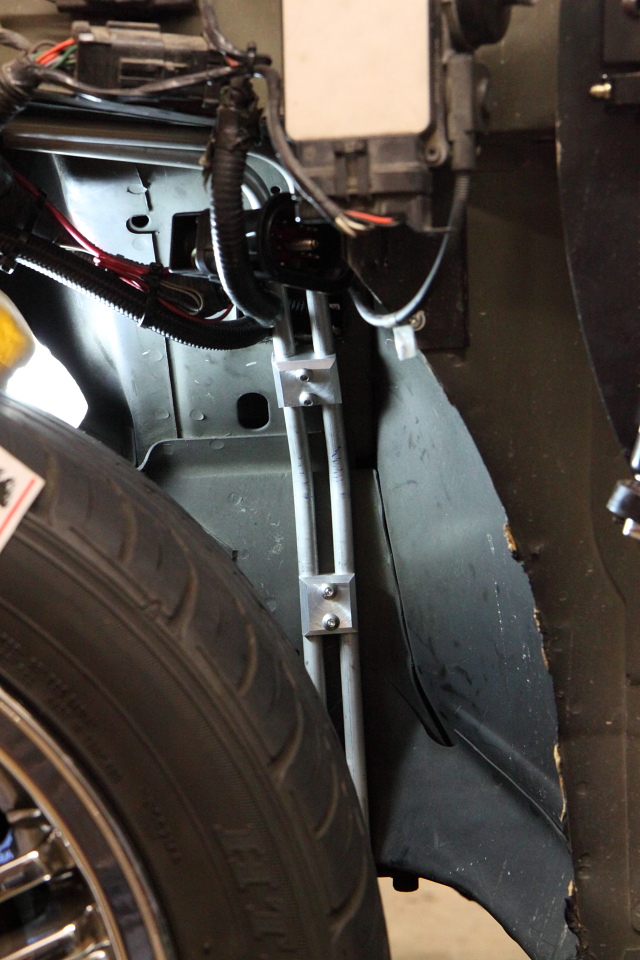

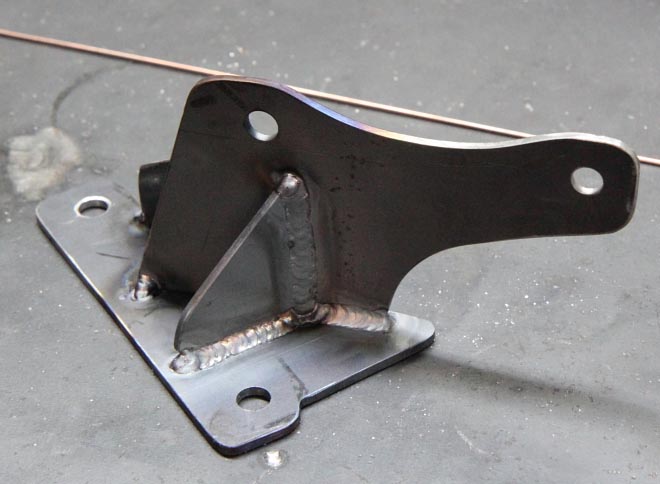

I didn't want the typical aluminum straps to hold the meth tank in place so

I fabbed up this bracket. It uses quick disconnect turnbuckles to hold the tank

in the tray. It just needs some powder coating. |

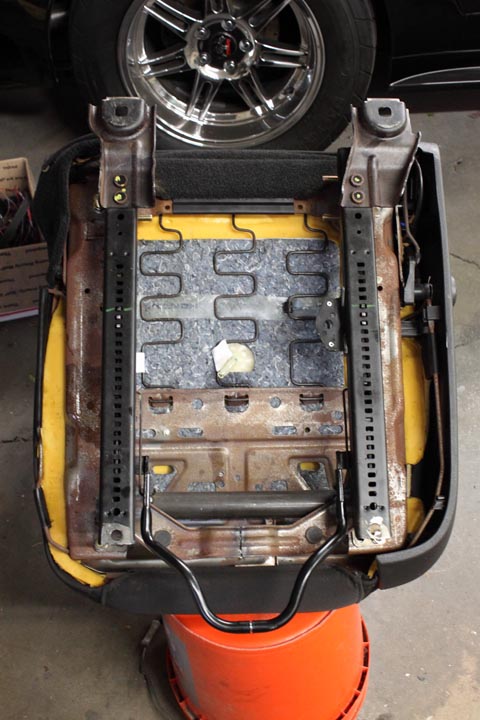

Adding Dyanmat to the floor of the trunk and back seat area. |

Adding Dyanmat to the floor of the trunk and back seat area. |

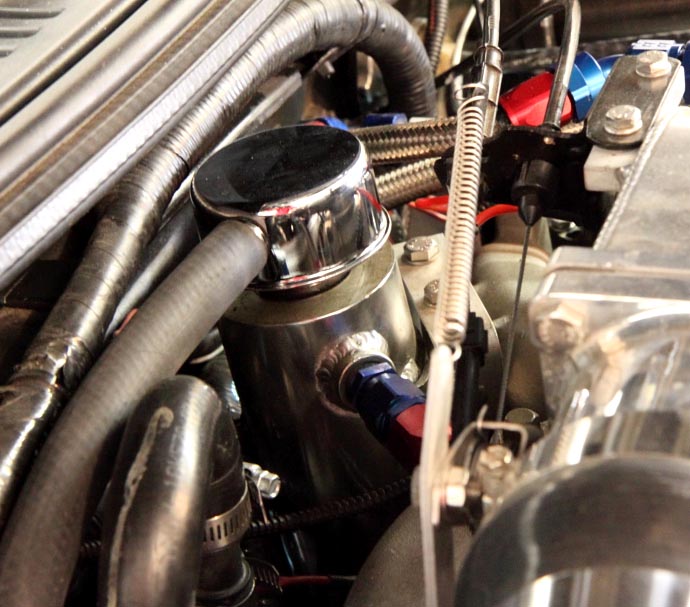

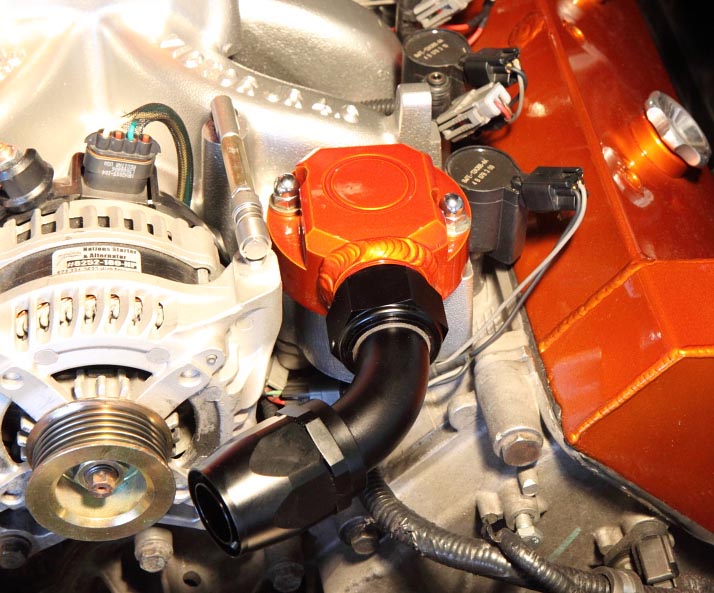

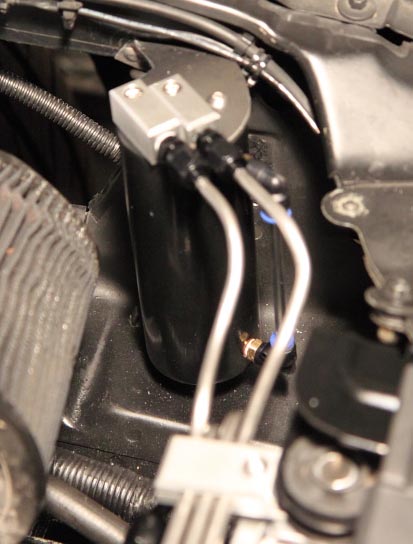

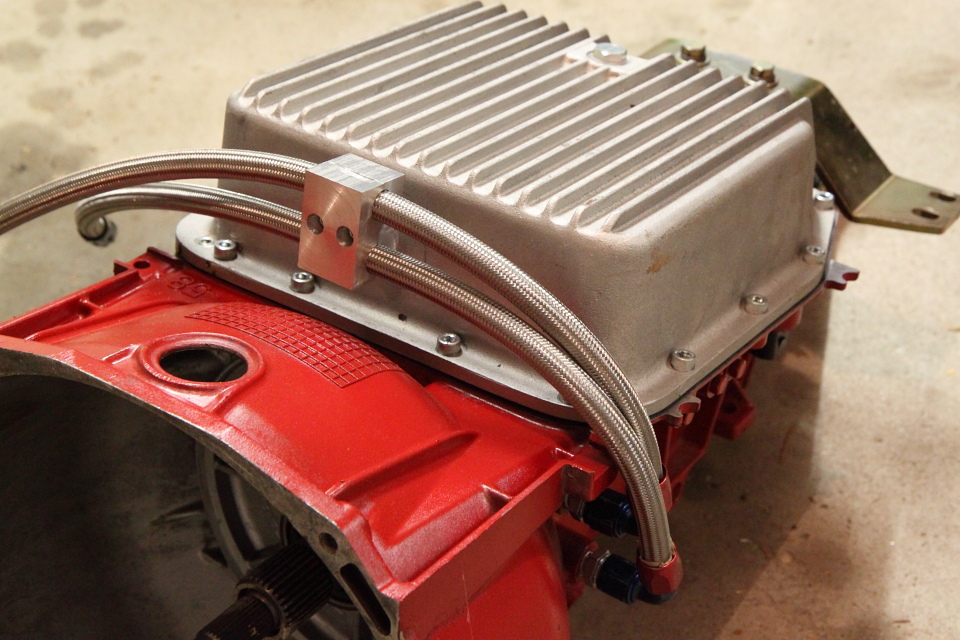

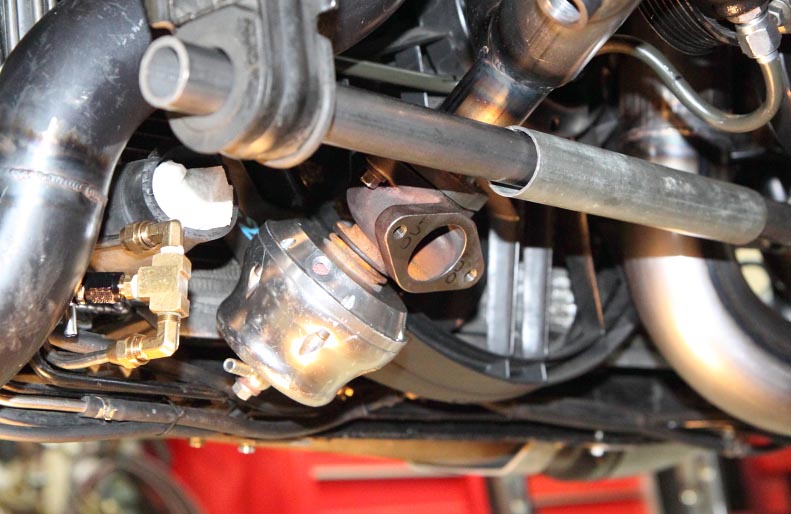

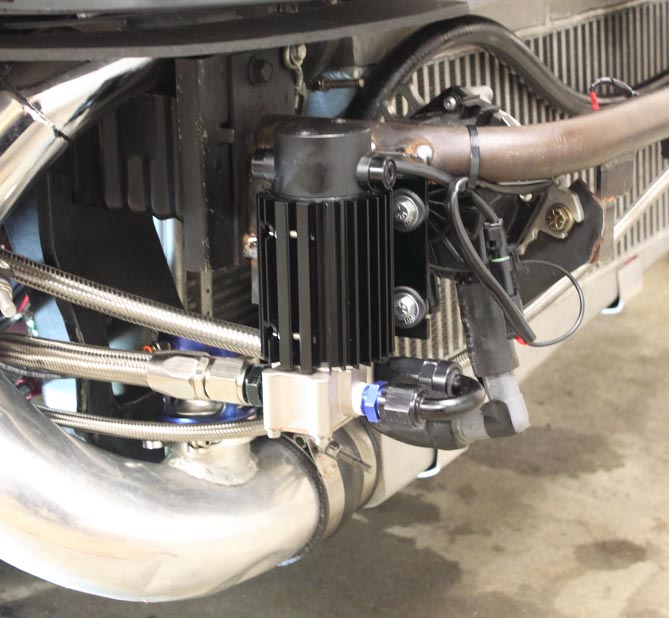

Made an electric crankcase evacuation pump.

The original motor kept burning up so I bought a different motor then made an adapter to bolt it to the smaog pump housing. |

This is the motor and the adapter bolted to the pump. |

The Alky Control kit has two LED's: one for activation and one for low alchy level. I mounted them both

in the boost gauge pod. |

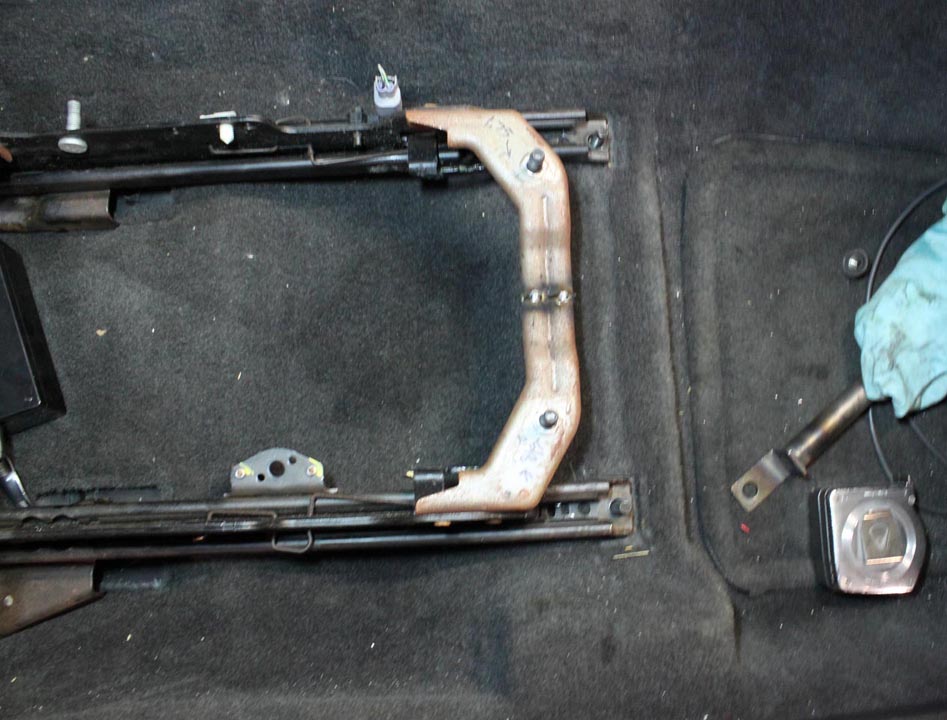

I mounted the alchy PAC controller under the passenger rear seat. |

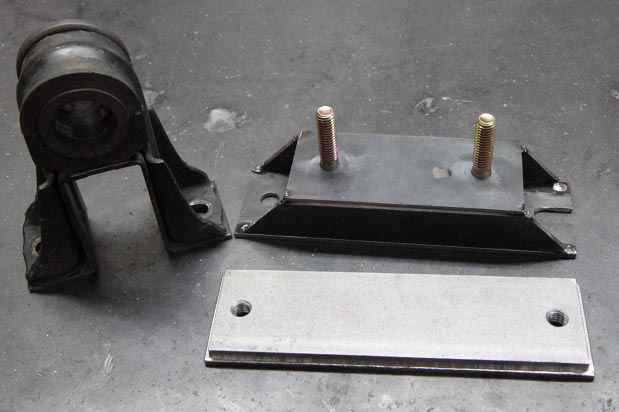

In order to quiet the ride I cut the small poly bushings

off the UPR A-arms and made my own that are larger. These larger bushings make the suspension feel softer when hitting bumps. |

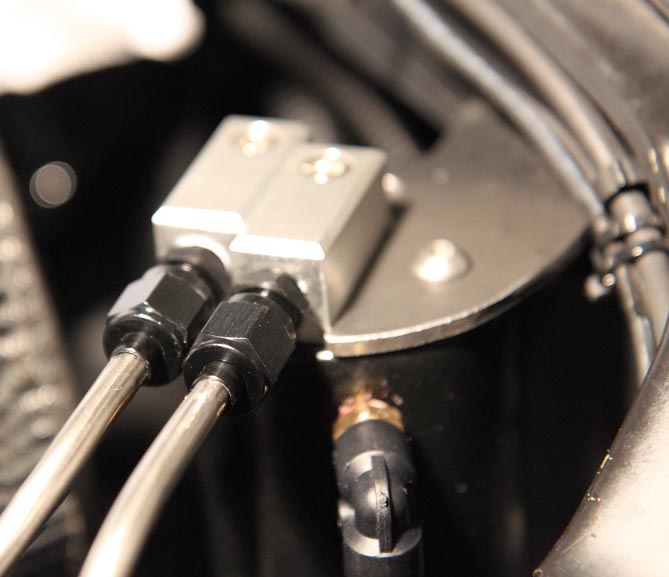

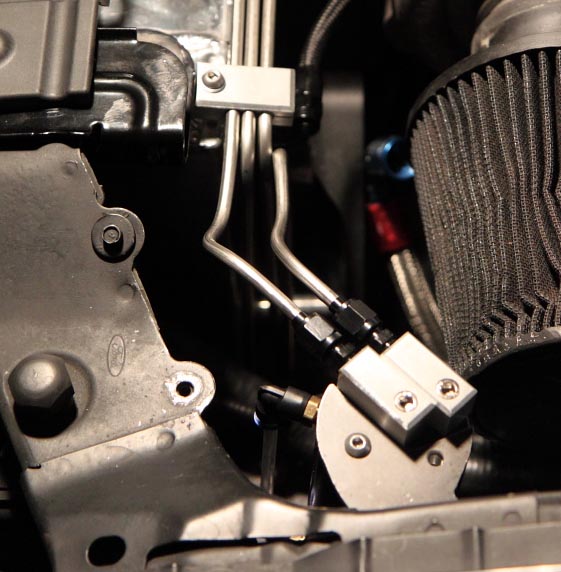

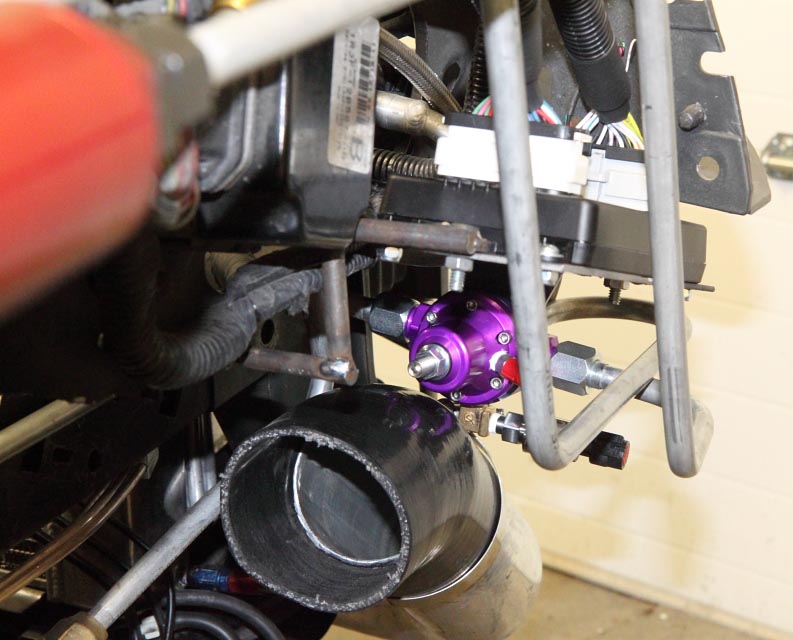

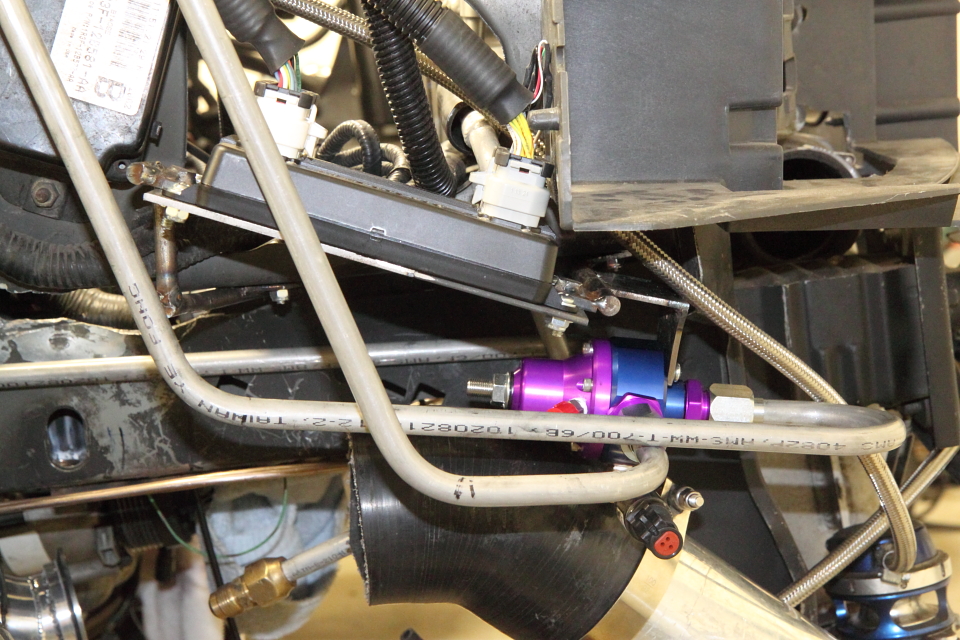

A single M15 alchy nozzle for now should handle 750HP.

It's fed with a stainless steel line from the tank. |

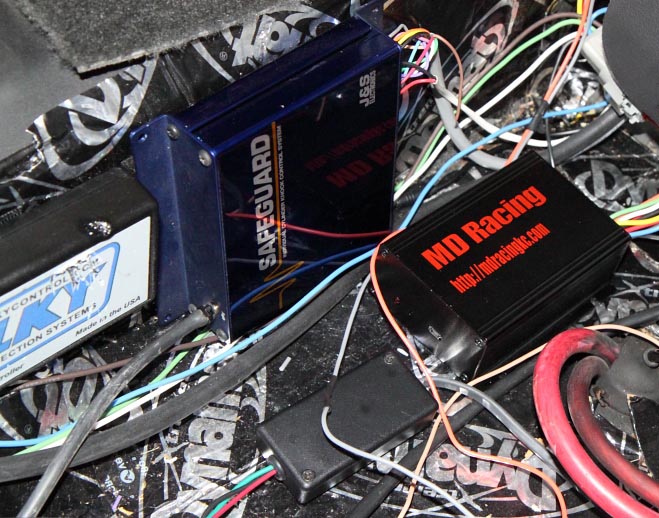

The SafeGuard knock detector will monitor knock in each cylinder.

If the unit hears knock it only pulls timing from that cylinder that is knocking. |

Here is the back of the SafeGuard unit. This should work great when tuning the alchy injection along with any other tuning I do. |

I mounted the SafeGuard knock controller and the Alchy Controller under the passenger rear seat. |

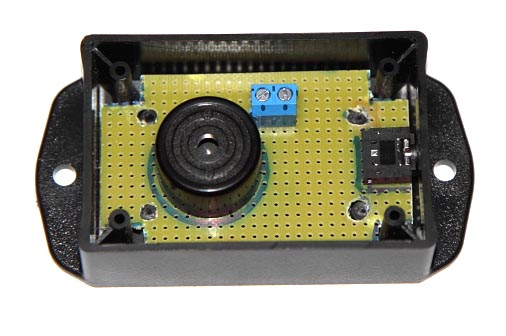

Here is the beeper I am making that will replace the knock gauge.

If the Safe Guard hears any knock then the beeper will go off which allows me to focus on other things. |

Here's the custom rearend Chris Neighbors built fo rme. He modified stock backing plates so I can still use the factory disc brakes. It's 1.25" narrower per side, 3.27's, 31 spline, etc.. |

I made a bezel to go around the E-Boost controller so it would fit

snug in the cup holder in the console. |

The bezel fits real snug in the cup holder and

around the E-Boost controller gauge. |

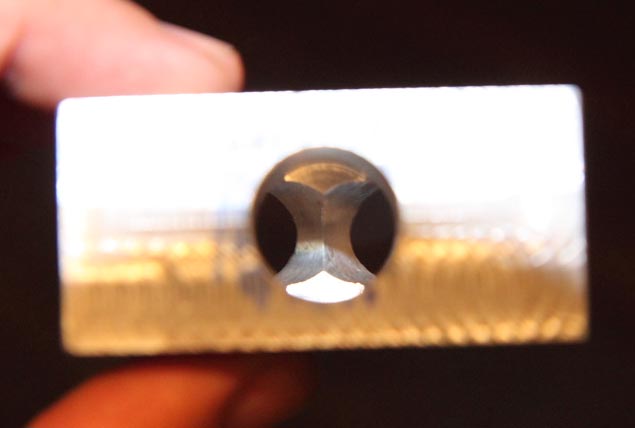

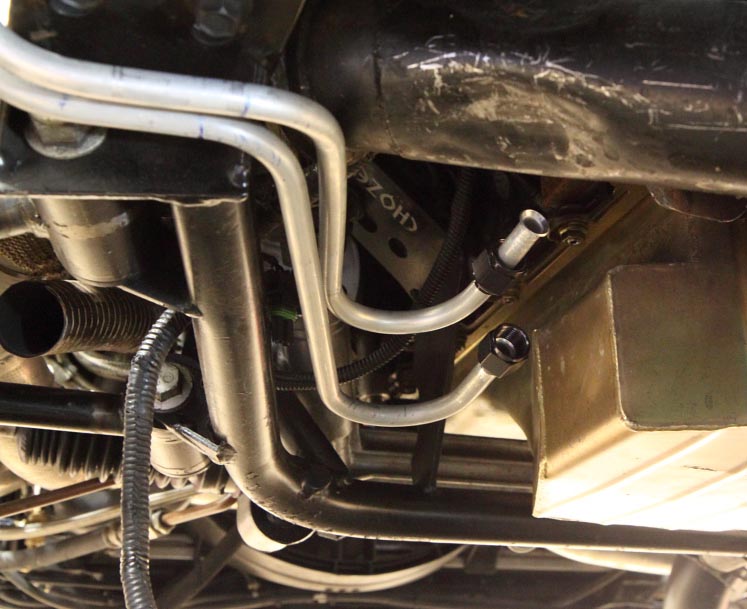

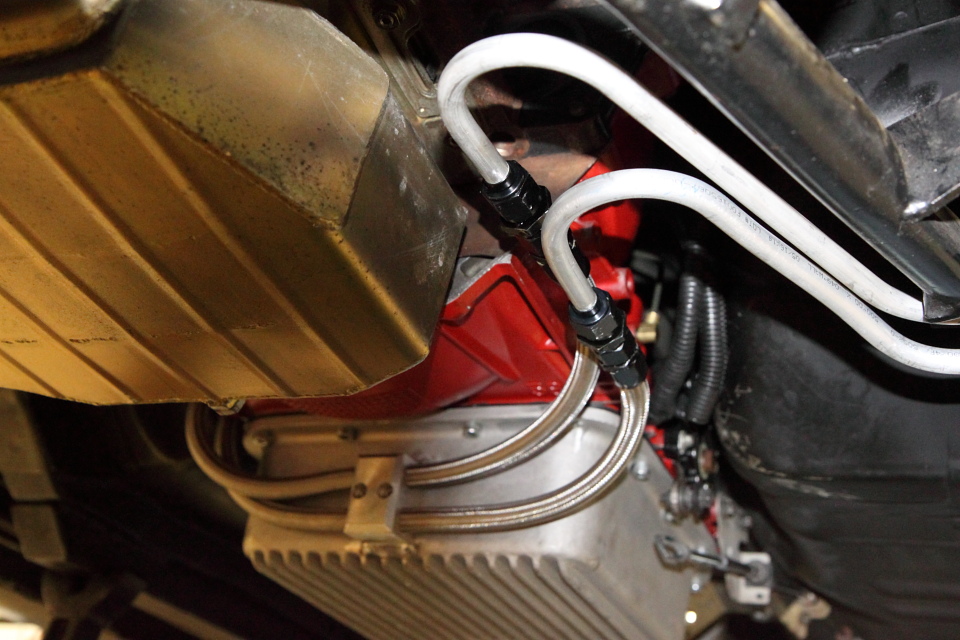

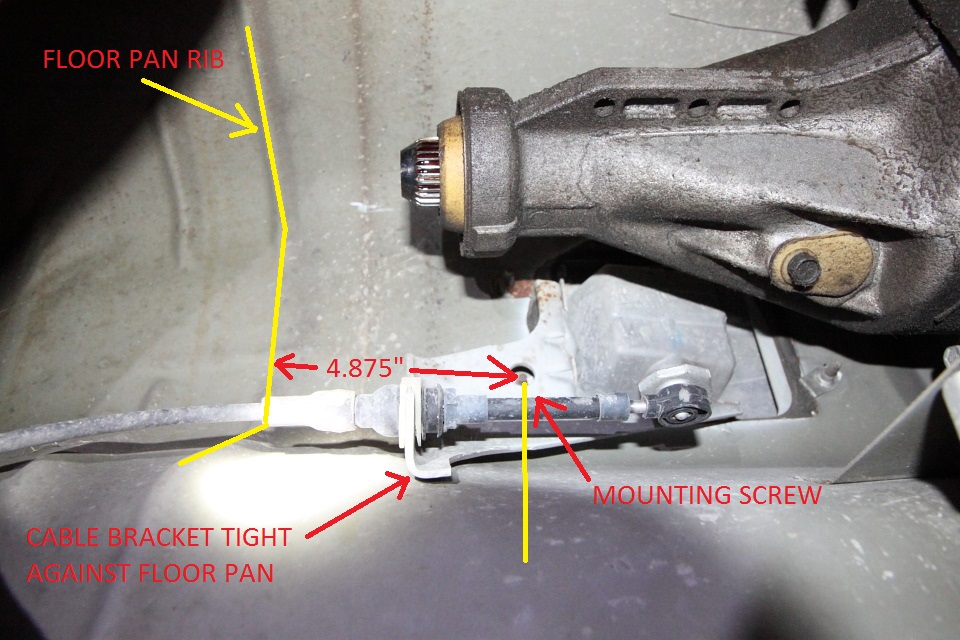

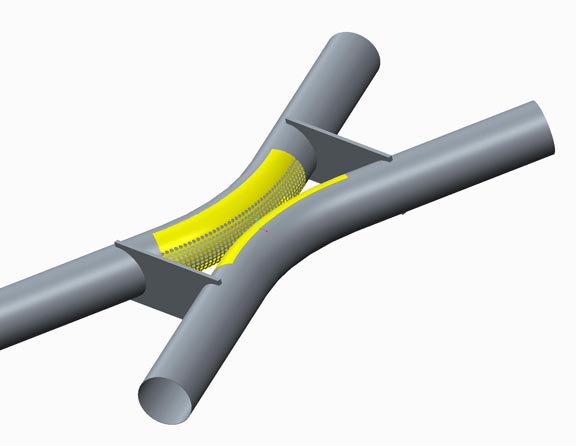

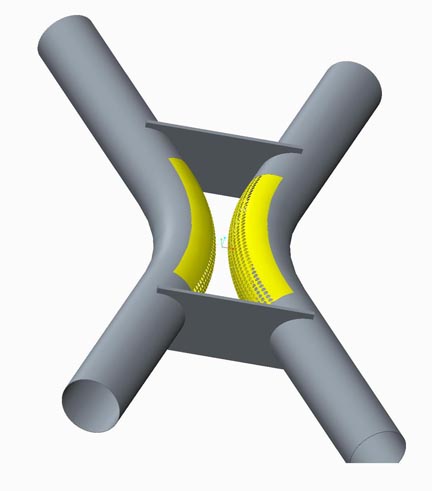

I made a resonator tube to cancel out the drone at 1800RPM but instead of the tube being a fixed length I made it adjustable. This is the "wall" that the sound waves hit and bounce back into the exhaust to cancel out the drone. |

The threaded rod moves the "wall" inside the capped tube essentially changing the internal length of the resonator tube. |

Since I made the internal length adjustable I can adjust it from 24" to 30" and currenlty it is at 27". Here is the finished product waiting to go in. Testing it at 27" cancels out all drone at 1800RPM and makes the car DAMN QUIET! |

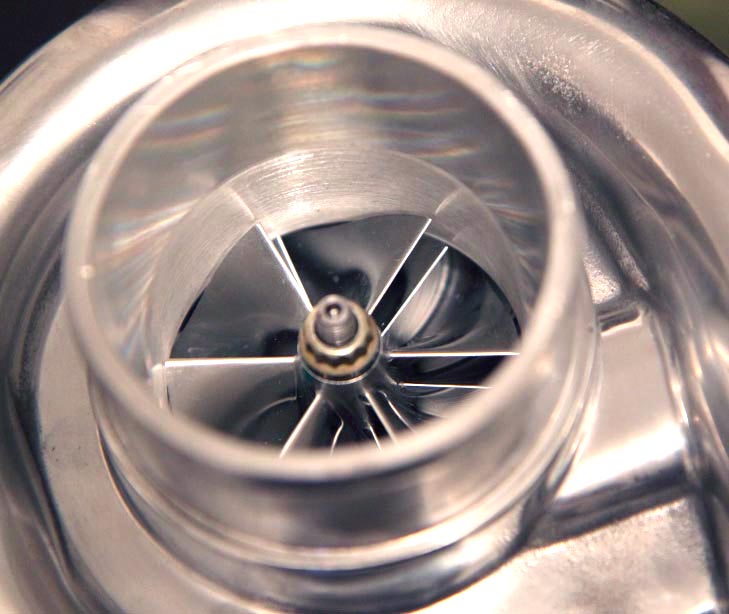

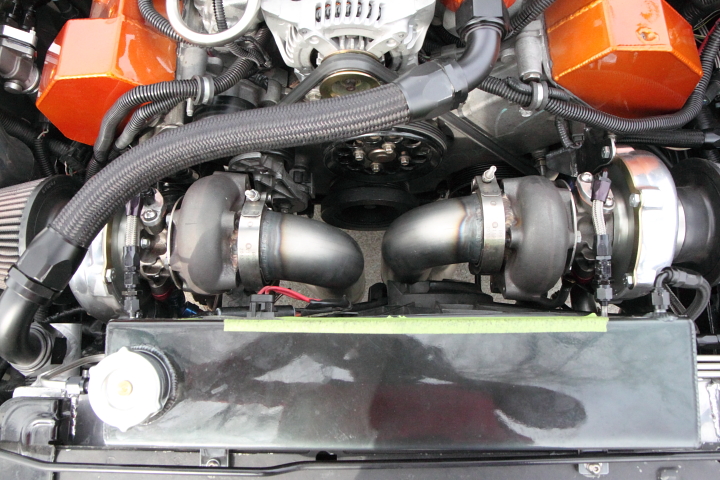

Here's one of the turbos: Supposed to be a 57mm T3/T4 w/ .63 AR and I hope to push 850HP out of the pair of them. If the pair of them are deemed capable of producing 850HP then I'll have the housings polished. Here's one of the turbos: Supposed to be a 57mm T3/T4 w/ .63 AR and I hope to push 850HP out of the pair of them. If the pair of them are deemed capable of producing 850HP then I'll have the housings polished. |

Cast Compresser Wheel.

Major dia: 74.8mm

Minor dia: 56.5mm |

Exhaust Side.

Diameter: 56.5mm

Supposed to be a .63AR |

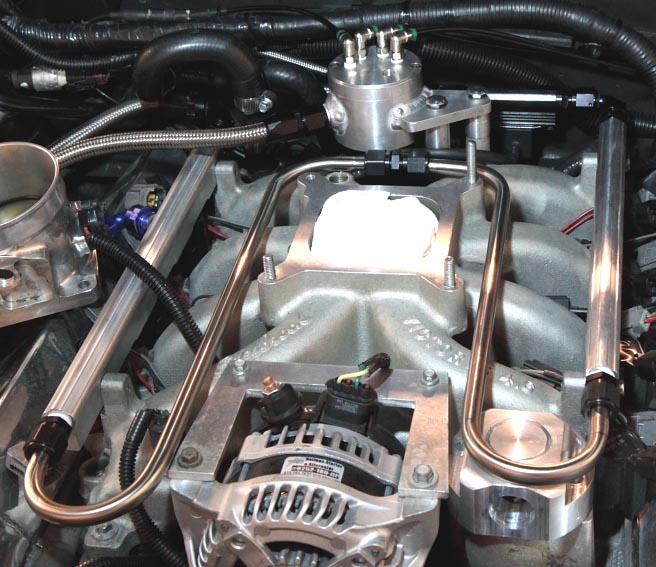

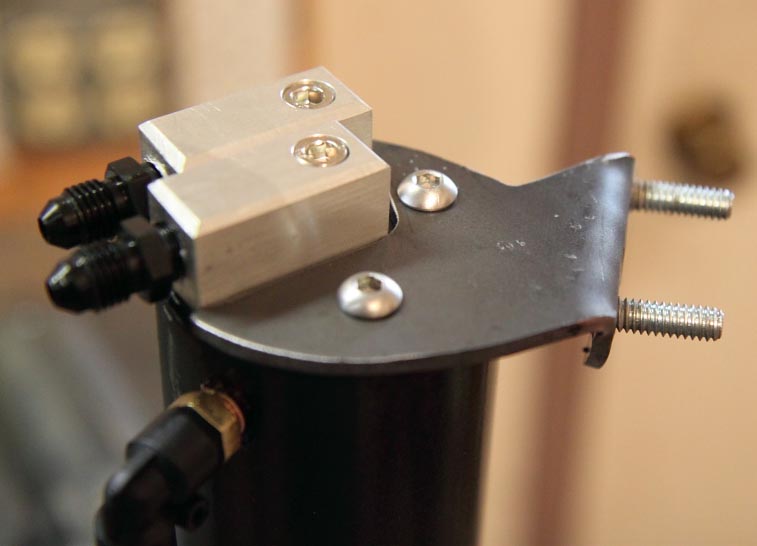

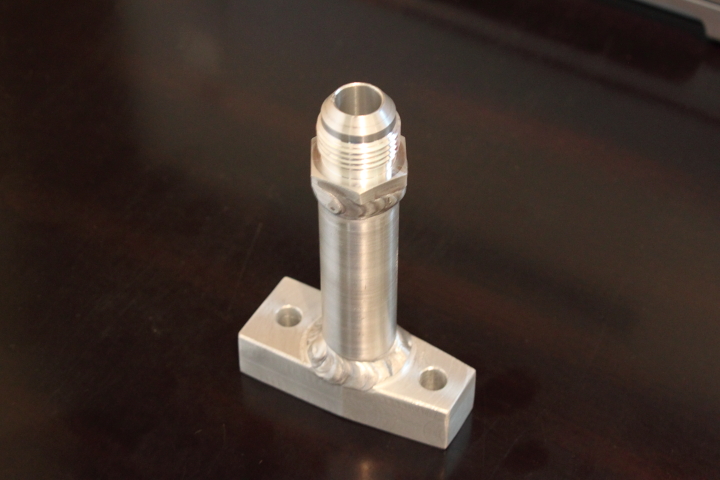

This is the Fuel Log I needed to make. I didn't like how the Y-logs split

the exit lines apart. This log will run the exit lines parallel to each other. |

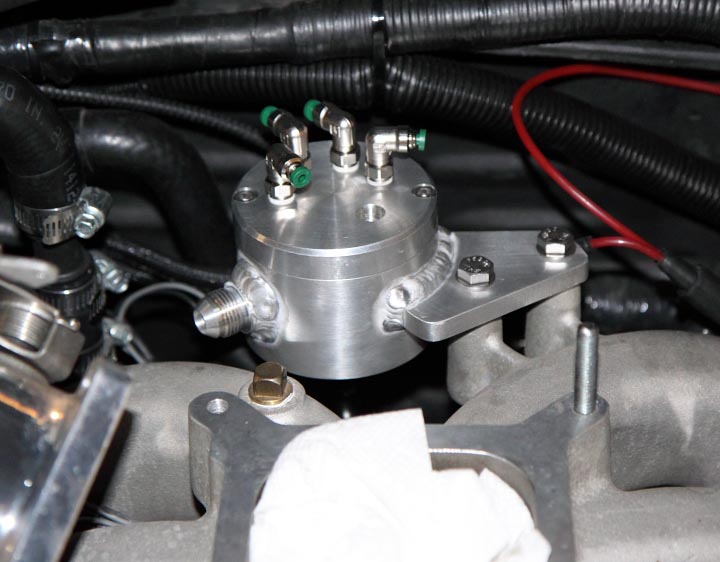

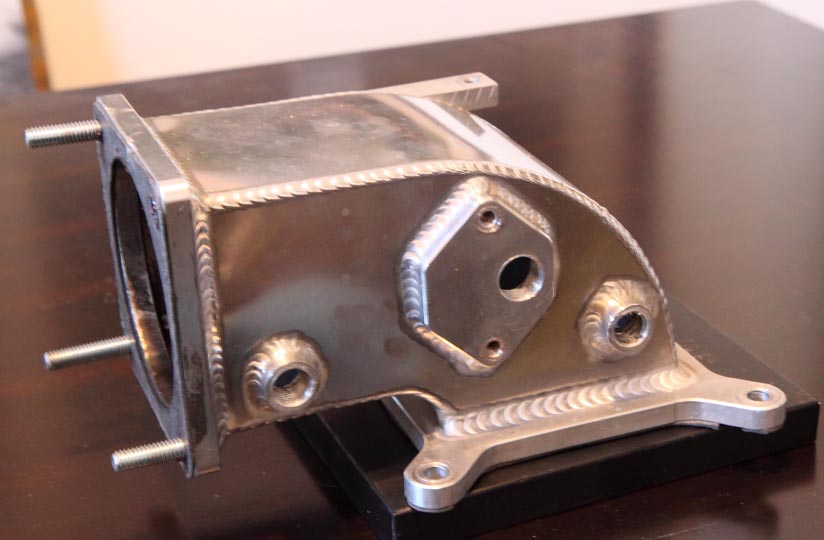

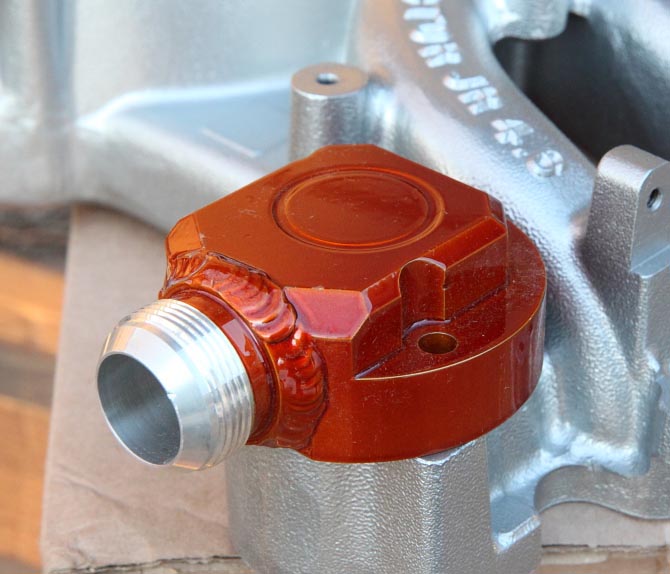

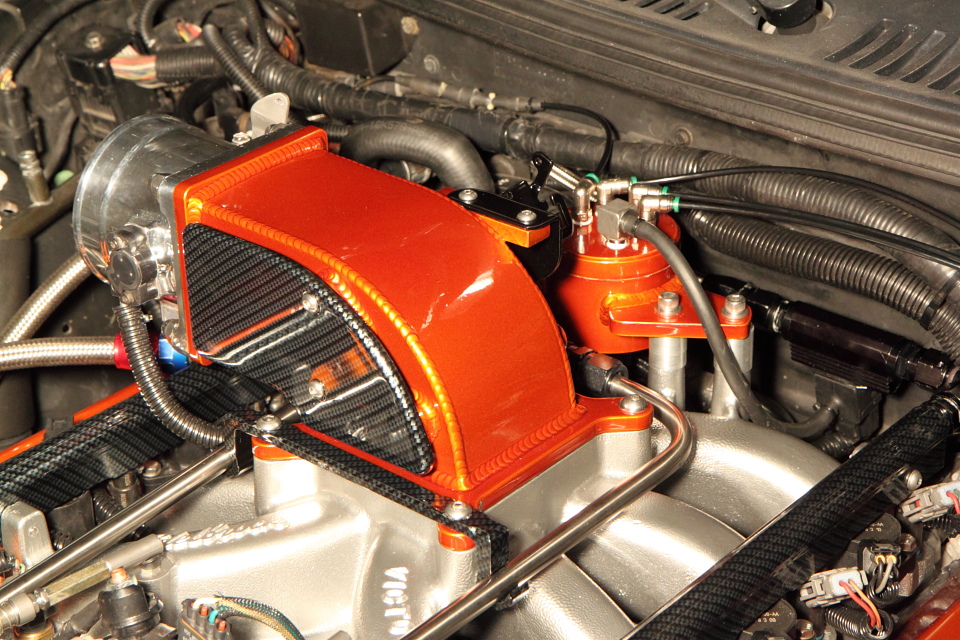

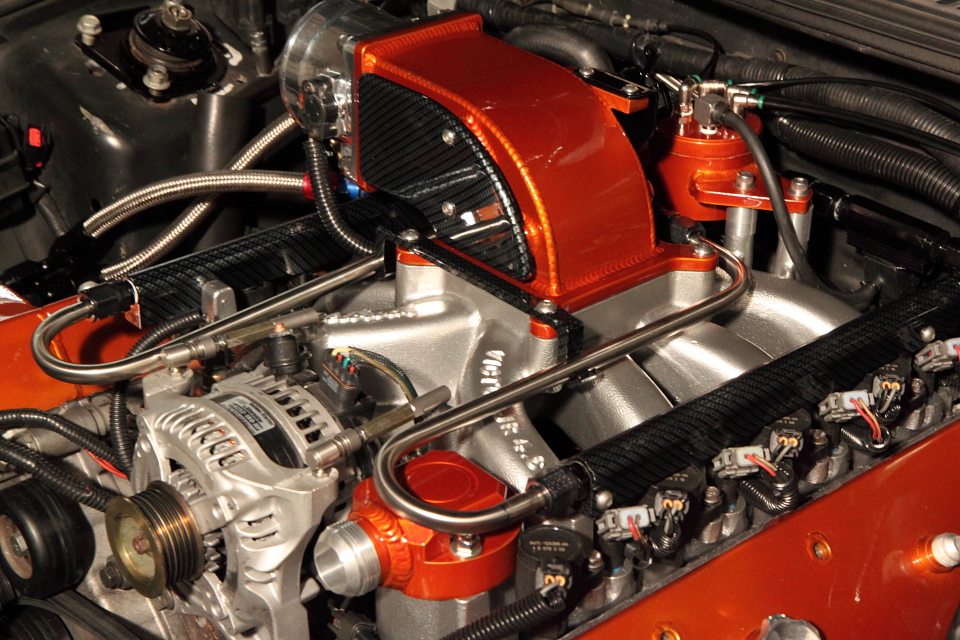

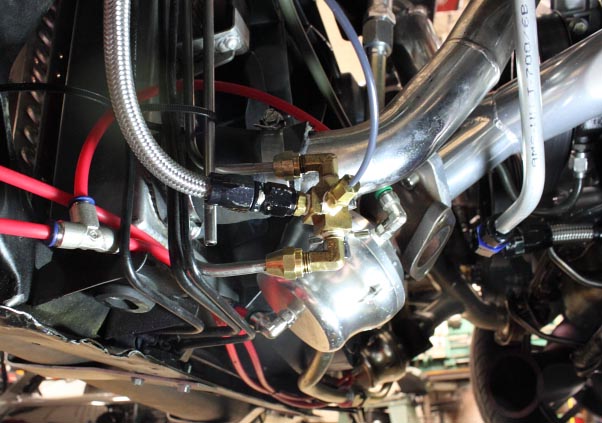

This is the Vacuum Block I made. I didn't like all the vacuume lines running to the front of the throttle body so this will be mounted behind the manifiold and all vacuum/boost lines will be run to this block. |

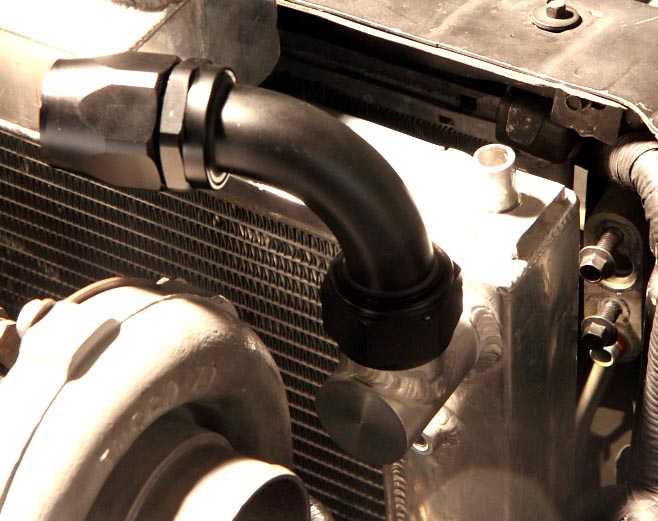

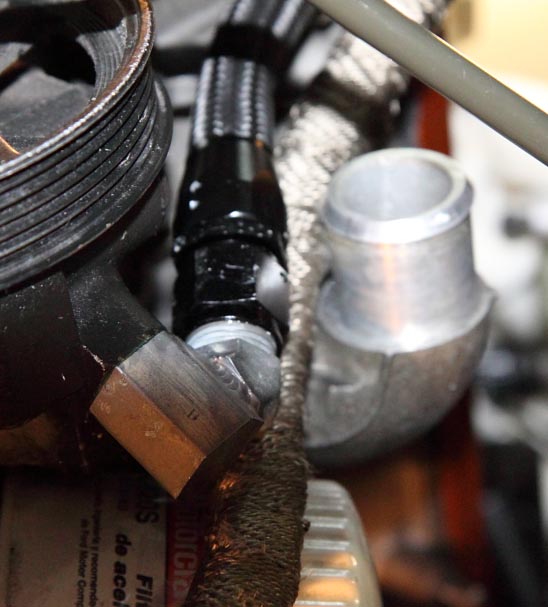

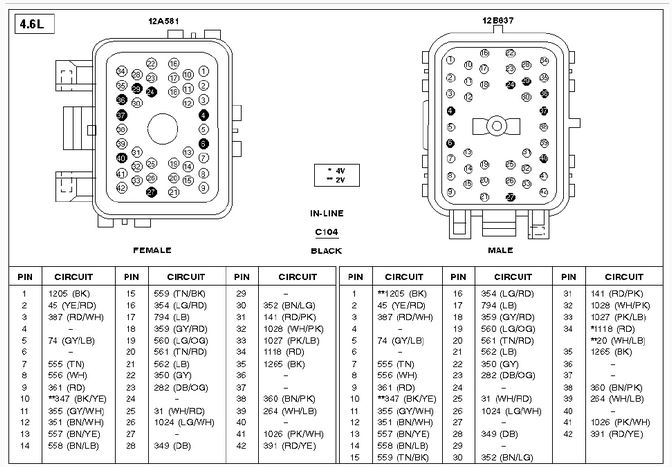

I couldn't find a t-stat housing that used a -20 fitting so I had to make one. |

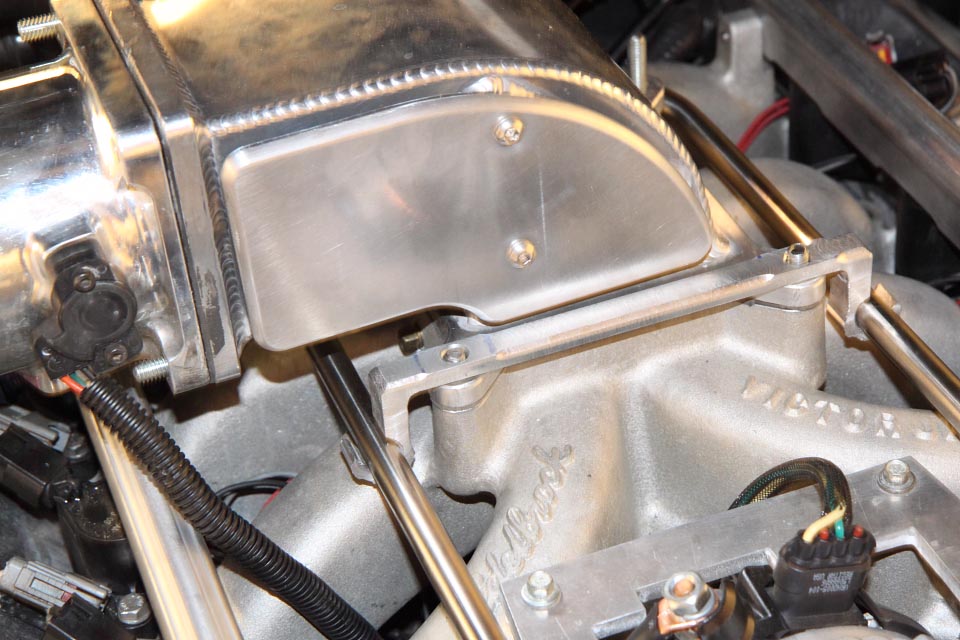

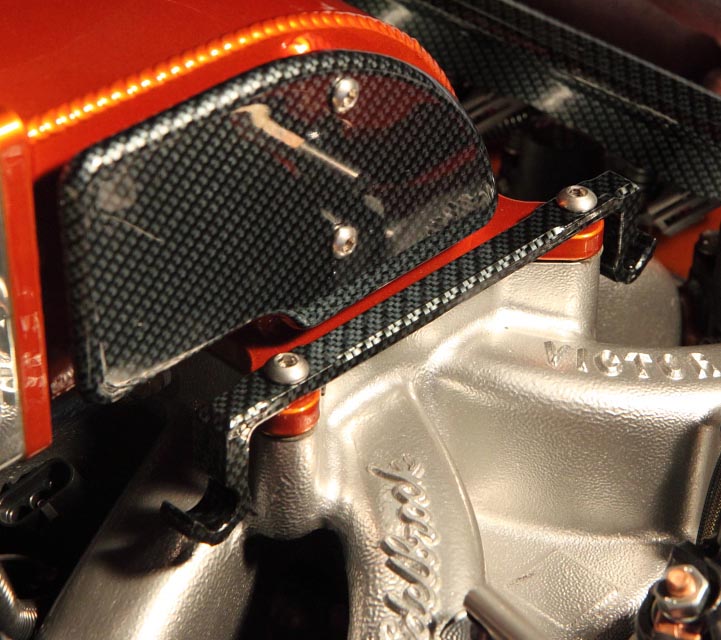

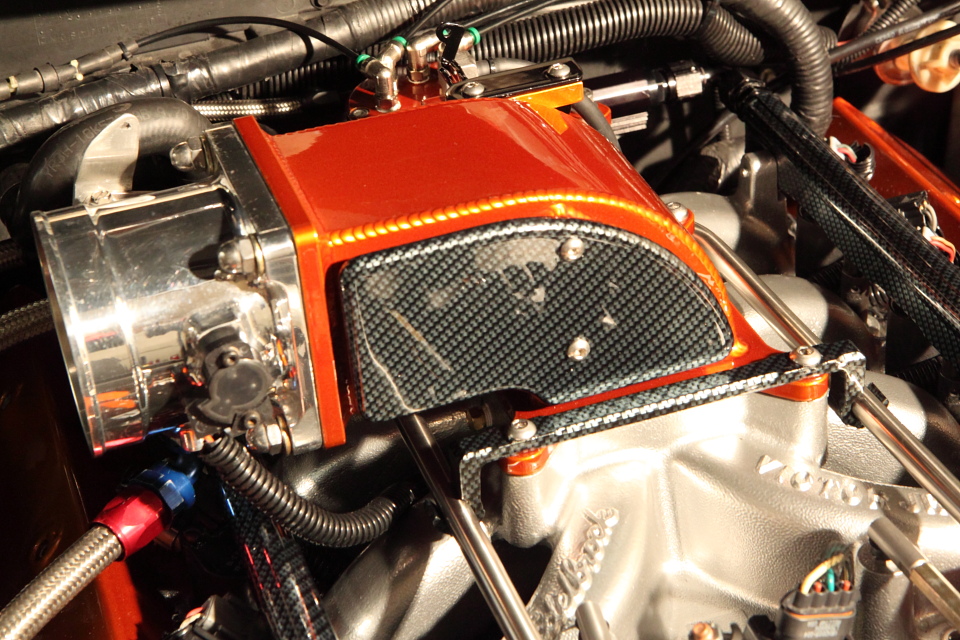

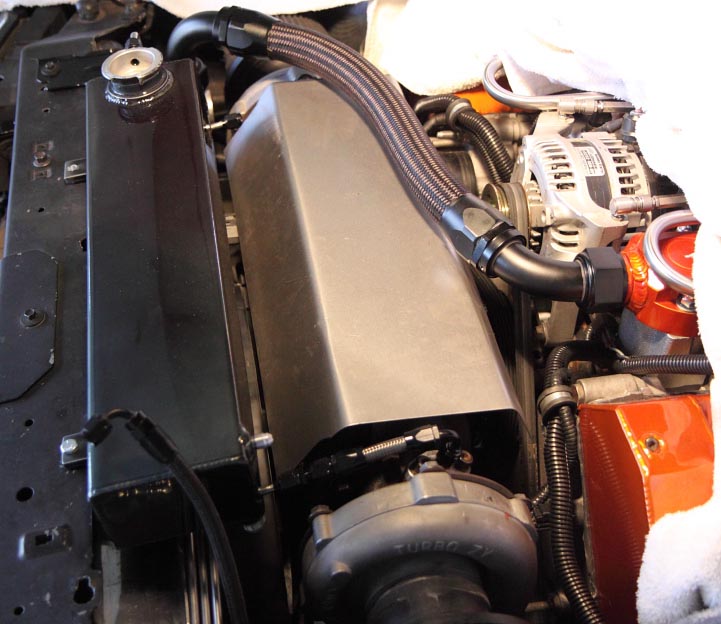

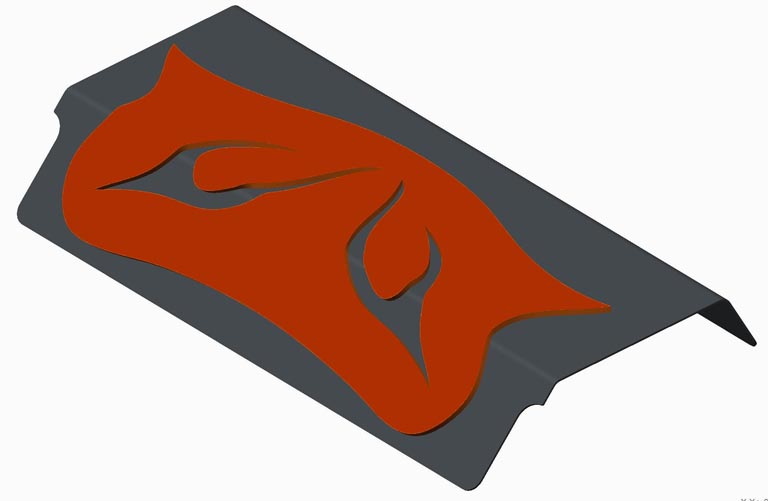

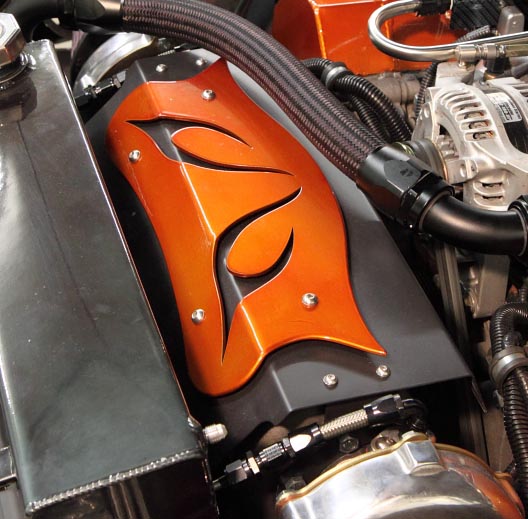

After removing all the hoses from the plenum I wanted to cover up the pipe plugs so I made a cover plate that will be hydro dipped in a black carbon fiber pattern along with the fuel rails. |

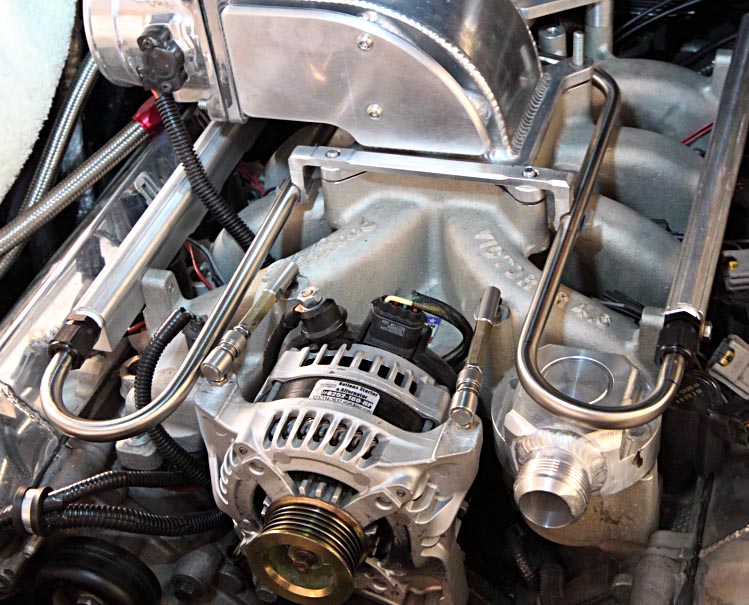

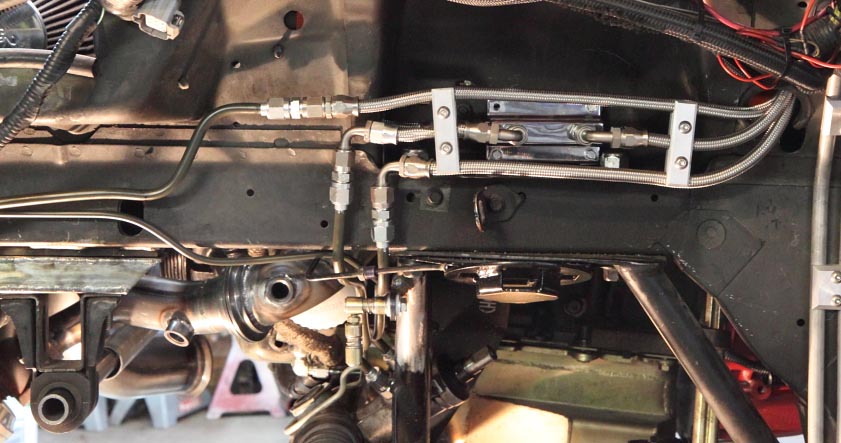

In order to keep the top of the motor organized I made some stainless steel fuel lines to connect the fuel rails at the front. The back of the rails are spilt and connect to a Y-Block in the fenderwell. This whole setup should gaurantee that each injector sees the same fuel pressure. |

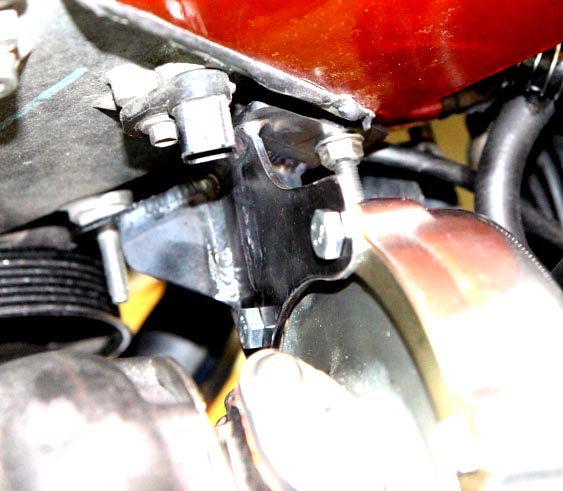

This is the fuel line support bracket that I made from a cut up fuel rail. This will support the lines so they don't vibrate loose. |

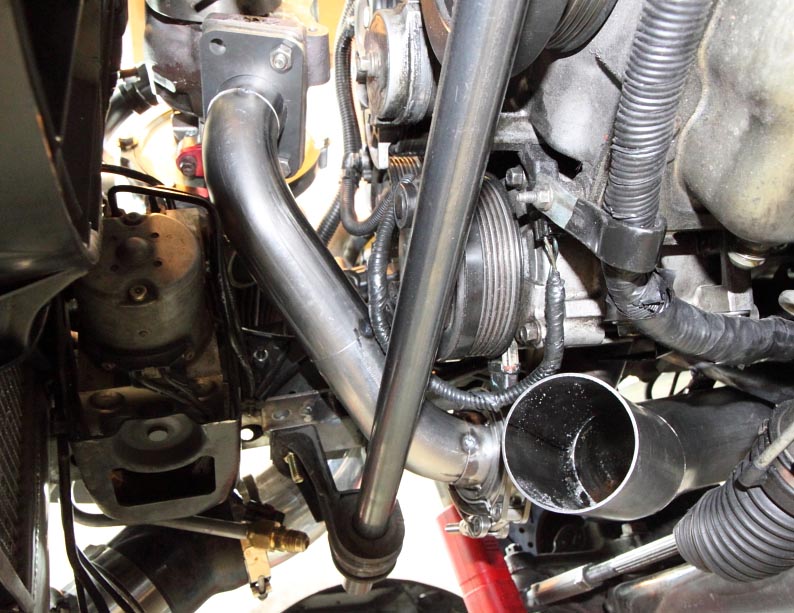

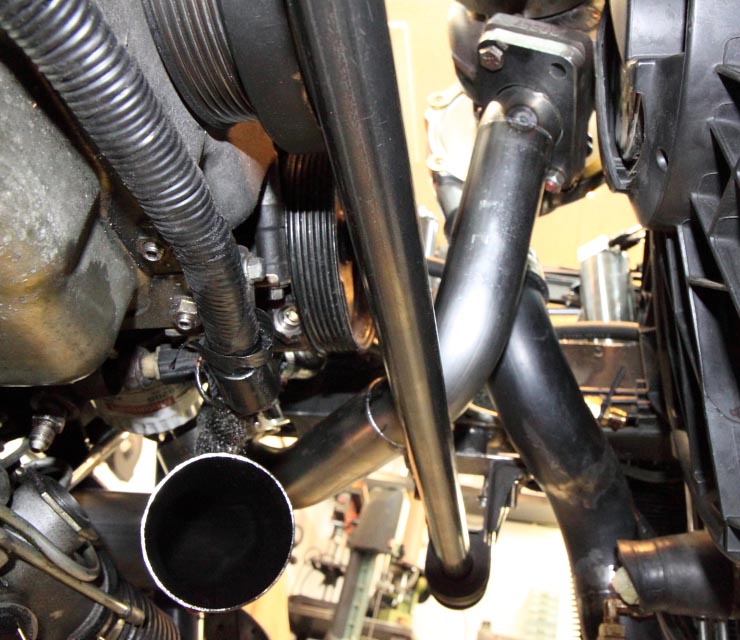

In this picture you can also see that I got rid of the ugly alternator support bracket and made some quick disconnect support rods instead. |

Fuel rail support. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If you're pondering some off the shelf turbos you should really give Brian a shout and see what he can put together specifically for your combo!

Brian Bissonette: bpe2013@hotmail.com

These units will make over 1000HP without even breathing hard! |

|

|

Billet Compressor wheel measurements:

59mm at the inducer

76mm at the base of the exducer

80mm at the maximum diameter of the fins |

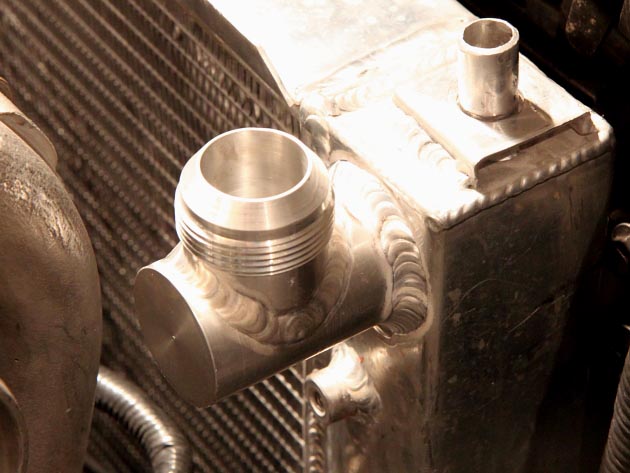

This is a radiator petcock I made that will have a 2ft braided hose permanently attached to it allowing me to put the hose into a pan/bucket and drain the radiator without it spilling all over the frame of the car.

Thanks for the idea Curtis! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

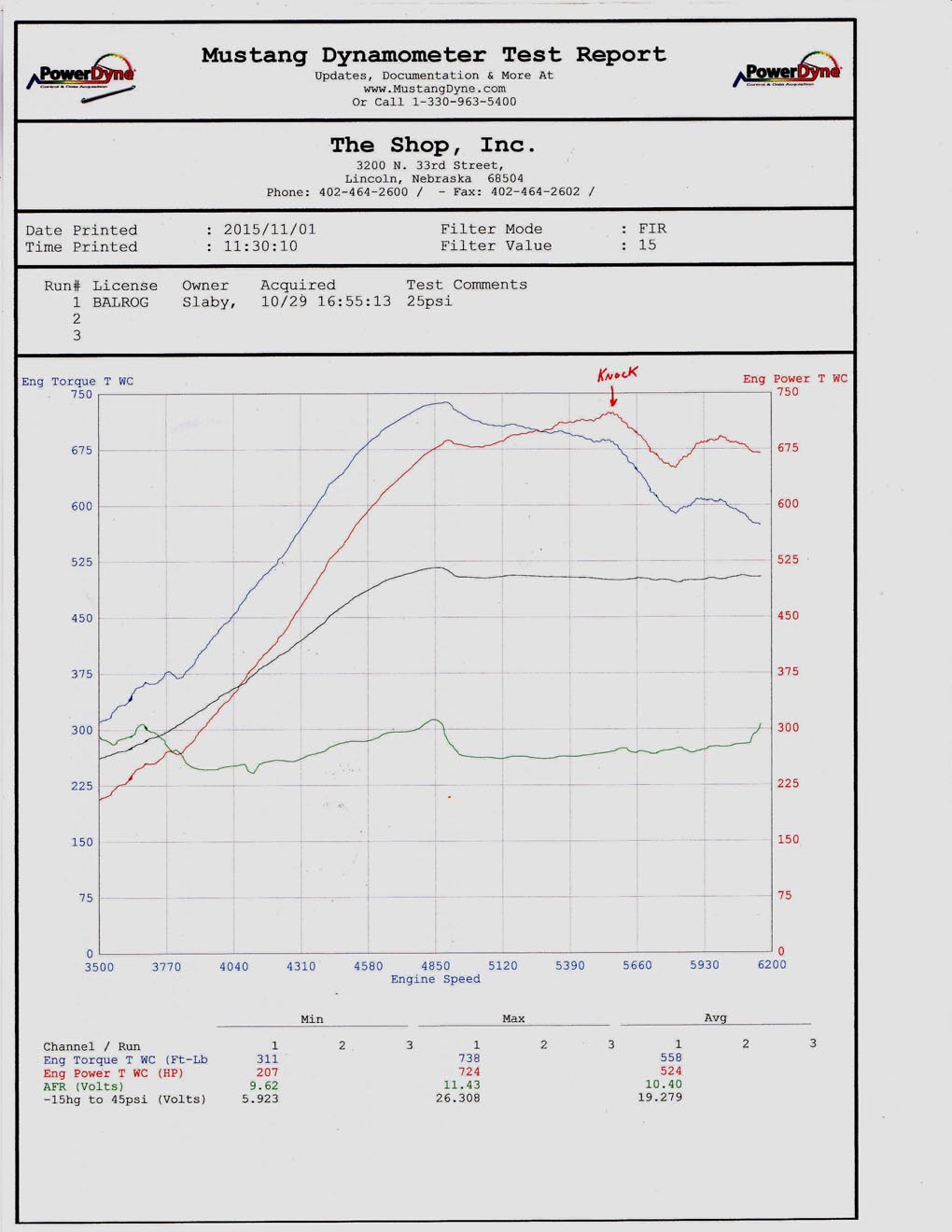

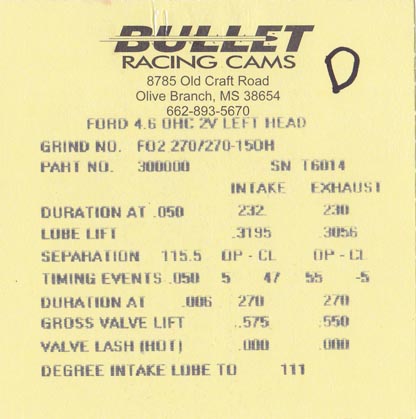

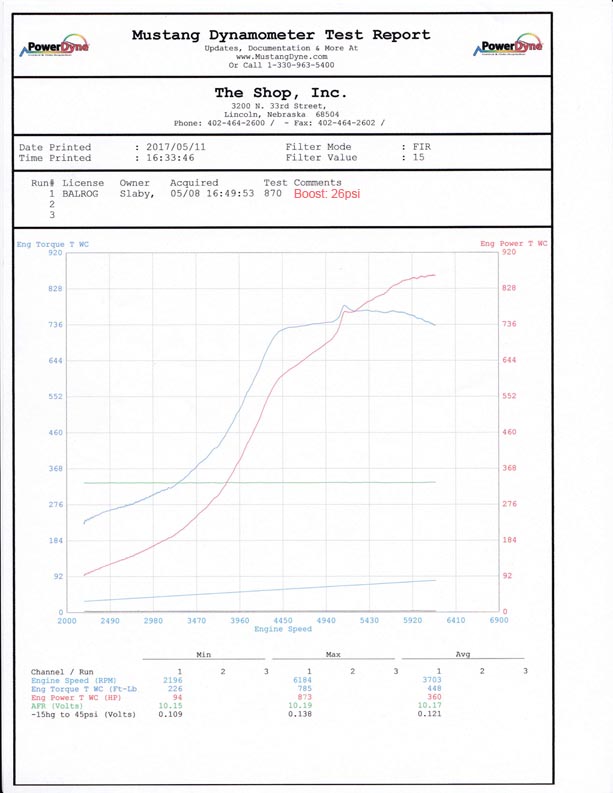

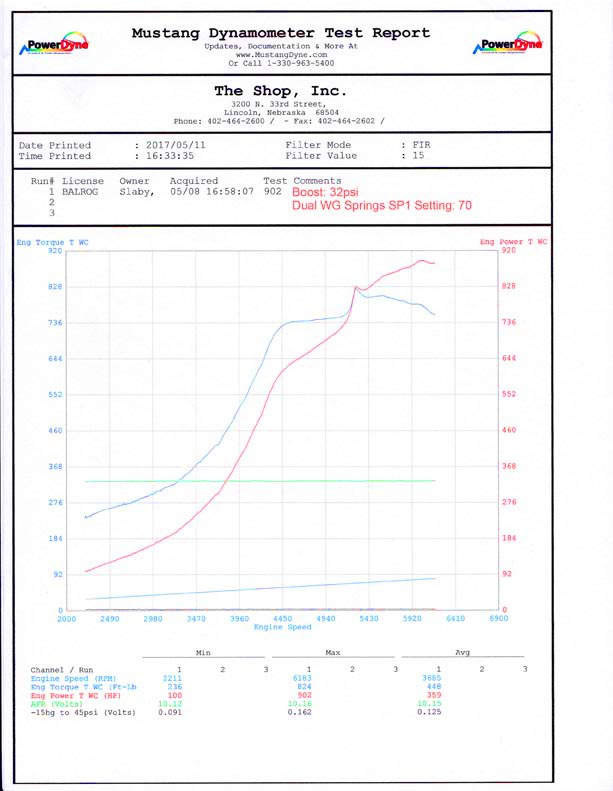

Dyno Graph - 91oct, Meth, 8* timing, 25psi boost |

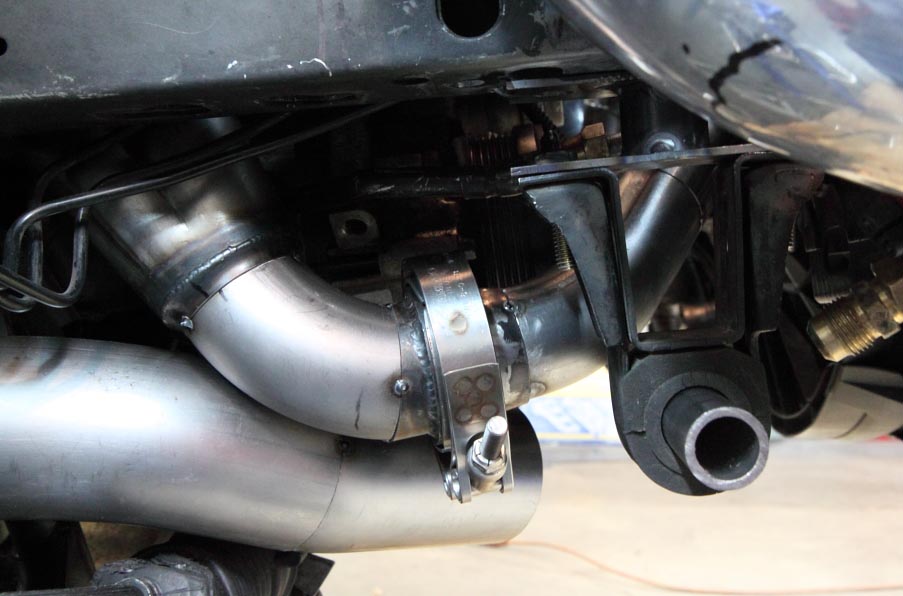

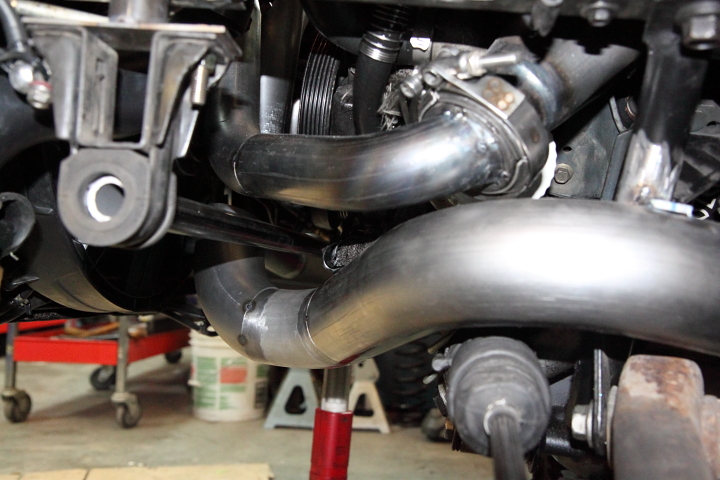

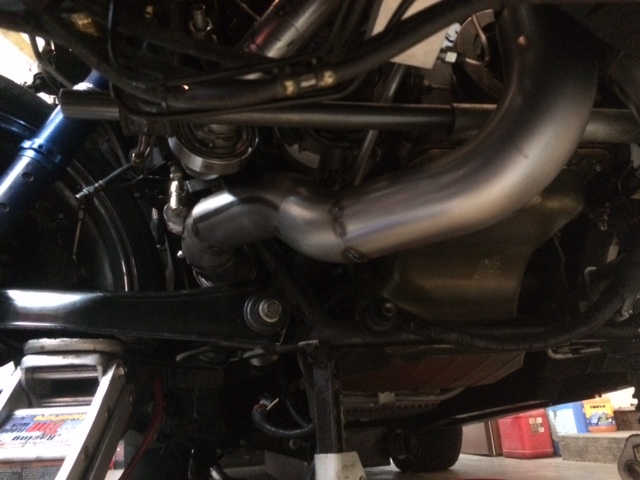

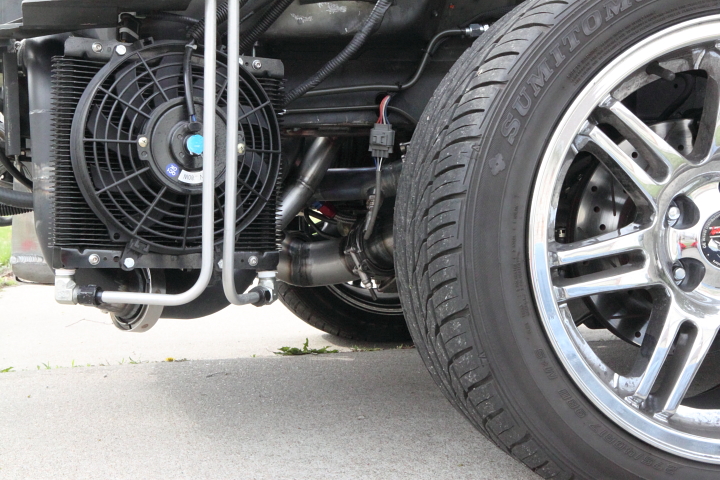

CG Fabrication headers with smaller 2.25" collectors which will

feed into smaller 2" pipes to the headers. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mold for bottom of the Hood |

Mold for top of the Hood |

Final assembled hood pieces ready for paint. |

|

|

2012 Coyote Seats |

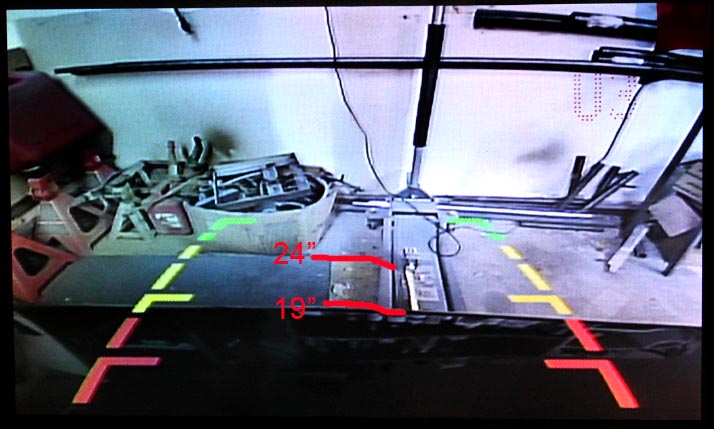

Backup Camera System |

|

|

|

|

|

|

|

|

|

|

|

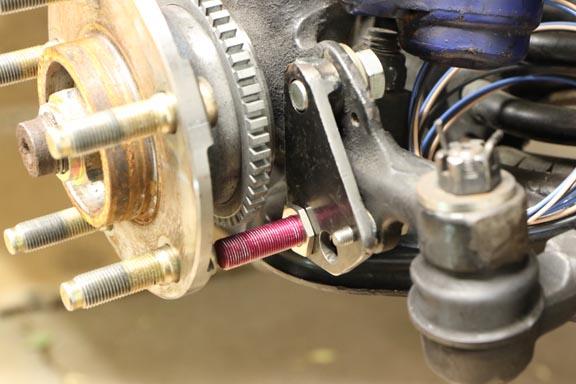

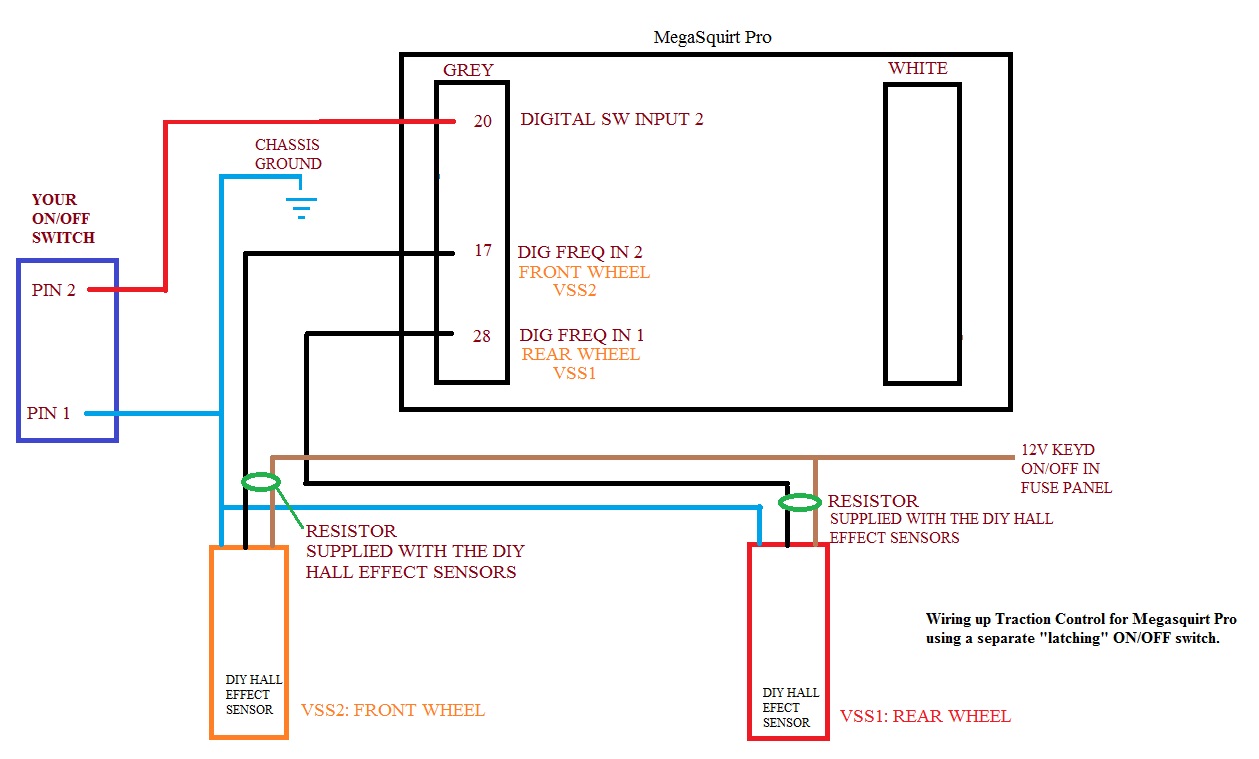

Traction Control Hall Effect Sensor |

Traction Control Hall Effect Sensor |

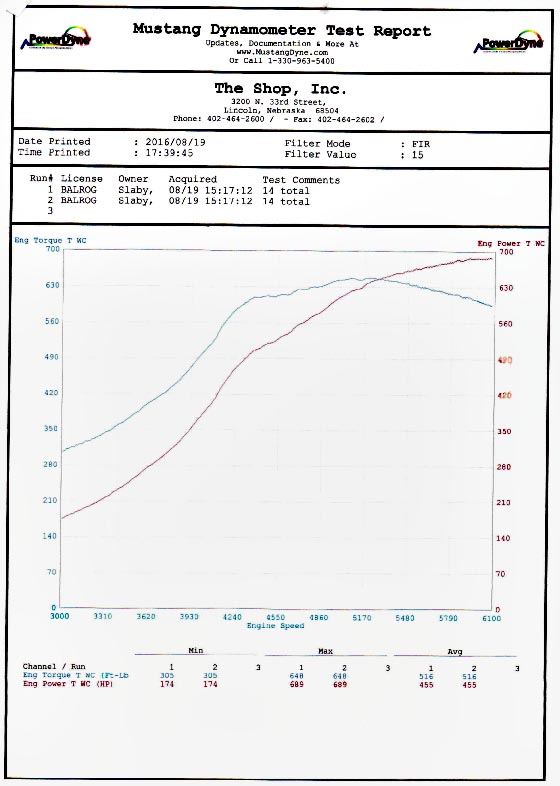

Traction Control Wiring |

|

|

|